Fully Automated Production Facility

Venom has a fully automated, ISO certified production facility with the annual production capacity of 35,000 MT. By integrating cutting-edge technology and automation, Venom’s production facility achieves unparalleled precision, efficiency, and consistency in the production process. With minimal human intervention, we can operate around the clock, ensuring a continuous supply of high-quality lubricants.

Over and above that, Venom production facility is equipped with 5 advanced technology filling lines and world-known Kawasaki’s fully automated robots and machinery which are programmed to monitor every aspect of the manufacturing process, from blending and quality control to packaging and distribution, resulting in reduced error rates and enhanced product quality, furthermore, reducing the cost through optimized resource utilization and energy efficiency. In an era where speed and quality are paramount, fully automated facilities are at the forefront of the industry, ensuring a reliable and sustainable supply of lubricants for a wide range of applications.

Research & Development

R&D efforts aim to optimize manufacturing processes, reduce costs, and minimize environmental impact. As technology and customer demands evolve, robust R&D programs are essential for oil and lubricants manufacturers to stay ahead, provide superior products, and contribute to a more sustainable future in the automotive, industrial, and machinery sectors.

Venom’s products are developed and improved by our skilled chemists and technicians. Our motto is to strive for excellence and provide the best possible solutions for customers. We have the advantage of a state-of-the-art laboratory and advanced technology equipment such as automatic viscosity and density meter, Elemental analyzers, Acidity & Alkalinity tester, Foaming & cold flow testers, Wear & Extreme pressure characteristics tester, to provide our customers with the highest standard products.

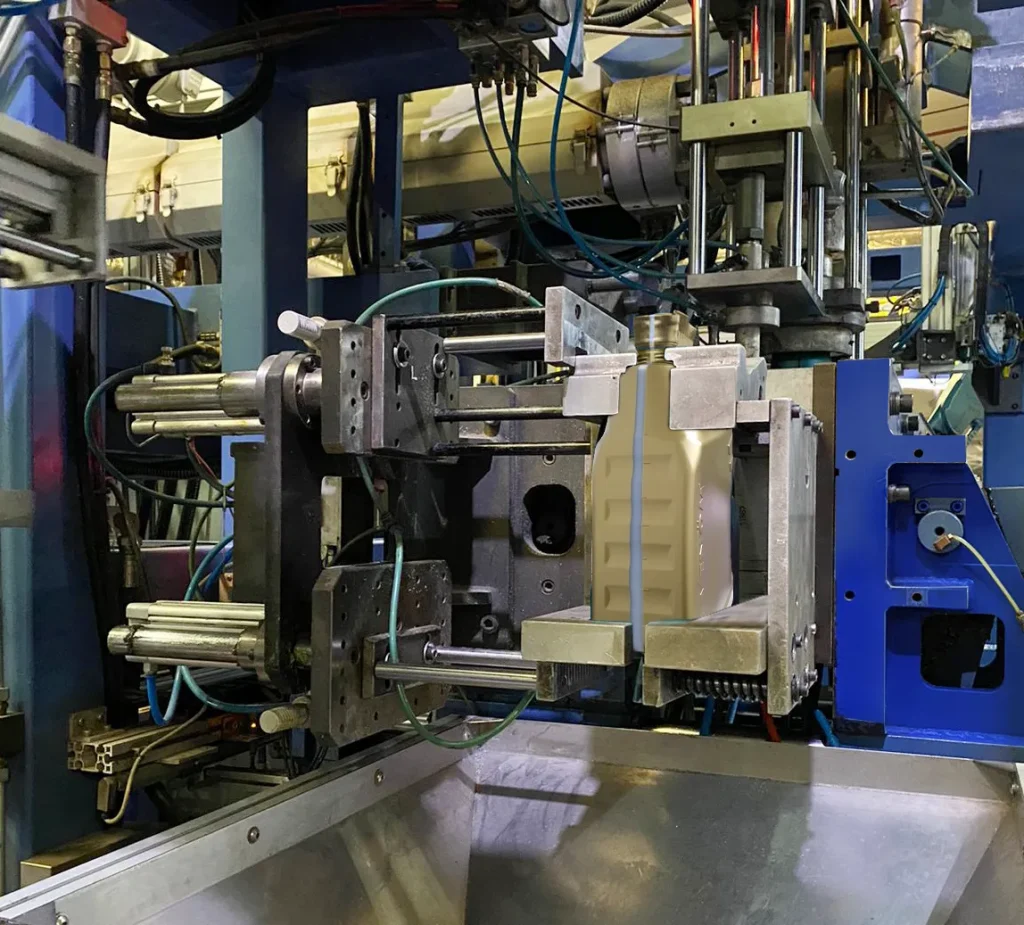

In-house Plastic Manufacturing Facility

As a part of its ISO certified production facility, Venom has the competitive advantage of having its own in-house plastic blow molding facility. Venom is equipped with 4 molding machines for different packaging sizes ranging from 1L, 3L, 4L, 5L, 7L up to 20L and 25L pails, production capacity of 25,000 gallons for 1L packaging, 10,000 gallons for 4L and 5L packagings, and 1,300 gallons for 20L packaging.

Additionally, Venom has an injection molding machine which is used to produce caps and shrouds along with a cap wadding machine. By having our own facility, the lead time to serve our valued customer has reduced and increased the cost efficiency. This also gives flexibility in supporting clients with their customized needs.

Logistic Support

At Venom, we plan, coordinate, and manage various logistics and supply chain activities in-house, related to the production, distribution, and delivery of our products. As a part of a successful logistics support process, we follow a wide range of activities including:

- Supply Chain Management

- Inventory Management

- Warehousing

- Distribution

- Transportation

- Demand Forecasting

- Quality Control

- Regulatory Compliance

With an in-house efficient logistic support provided to our customers and partners, we guarantee to minimize the operational costs, to reduce lead times, to ensure product availability, and to enhance our customer satisfaction.